Electrodeionization – EDI modules

High purity water by MEGA - innovative continuous electrodeionization process

Did you know?

MPure™ EDI technology delivers high purity water continuously with no chemical and regeneration needs.

Electrodeionization (EDI) by MEGA

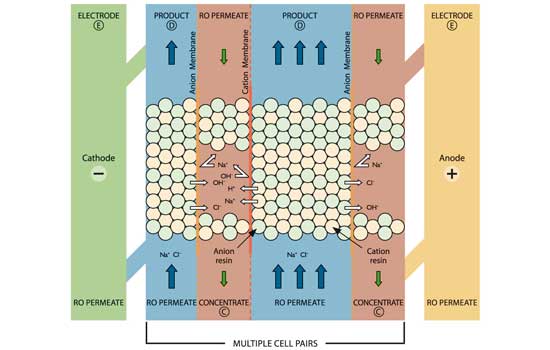

What is electrodeionization?

The benefits of continuous EDI compared to conventional MIXED BED technology

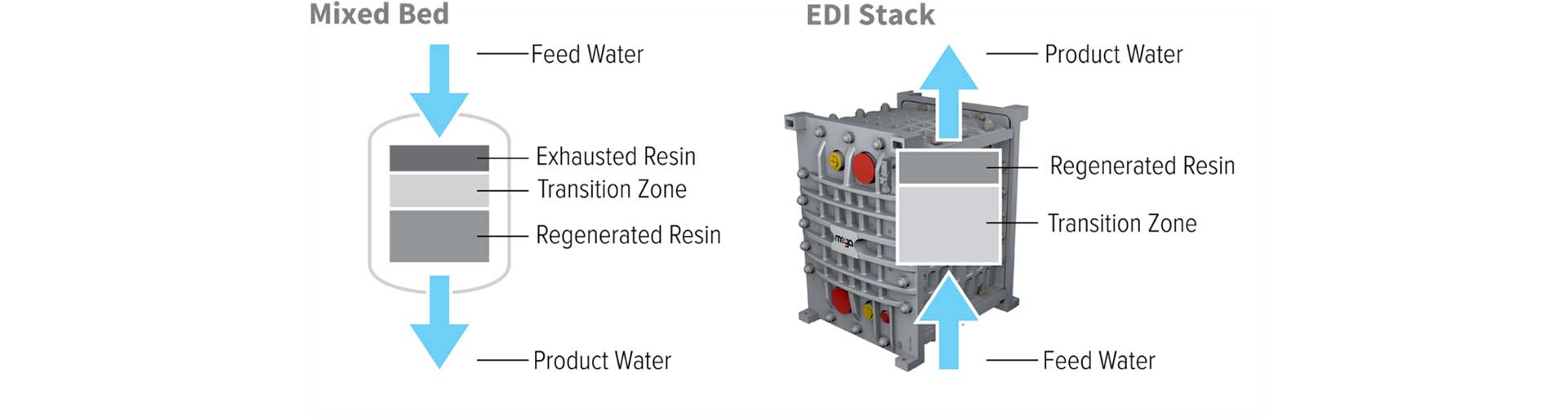

Using conventional mixed bed technology, the cation and anion resins must be regularly regenerated by acid and caustic.

On the other hand, electrodeionization is a continuously running process with no need for downtime for resins regeneration. EDI operates without regeneration chemicals, so no equipment such as acid and base storage tanks are required. This dramatically reduces the footprint of the entire EDI water polishing technology. In general, electrodeionization is a flexible system that is easy to operate and maintain.

MPure™ - EDI modules from MEGA

Request a free quotation for your electrodeionization project

Our experts are ready to find the best EDI solution for your polishing water project.

Please, fill out the form below. We will reach out to you as soon as possible.

Interested? Contact us.