Electrodeionization by MEGA - the solution for hydrogen production

Reduce water treatment costs for green hydrogen production

Did you know?

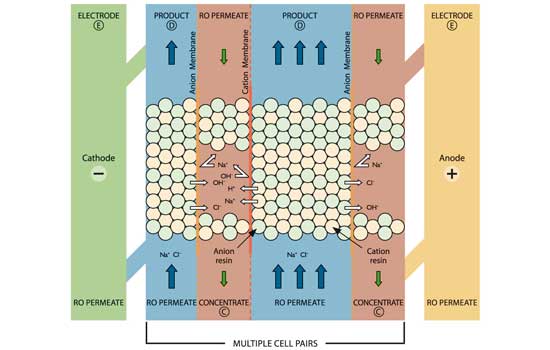

Electrodeionization from MEGA produces ultrapure water with a conductivity of up to 0.055 µS/cm. Continuously and without the need for regeneration chemicals.

Production of ultrapure water for hydrogen production

Find out how MEGA's electrodeionization can help you with (not only) green hydrogen production

Electrodeionization increases sustainable hydrogen production by reducing operating costs through higher water yield. This is achieved without the need for column regeneration chemicals. The ultrapure water produced meets the demanding quality requirements for advanced hydrogen production. Expressed as an electrical conductivity of up to 0.055 µS/cm at 25°C or as a resistivity of 18.2 MΩ∙cm.

MEGA provides water treatment technology for the production of green hydrogen that meets strict water quality criteria for use in electrolyzers, typically <1 µS/cm.

If you are experiencing problems with water for your green hydrogen project, we are happy to help. Learn about our solution for producing ultrapure water.

Water treatment for green hydrogen production

Request a free quotation for your Ultrapure water (UPW) project

Our experts are ready to find the best solution for your EDI ultrapure water project.

Please, fill out the form below. We will reach out to you as soon as possible.

Interested? Contact us.